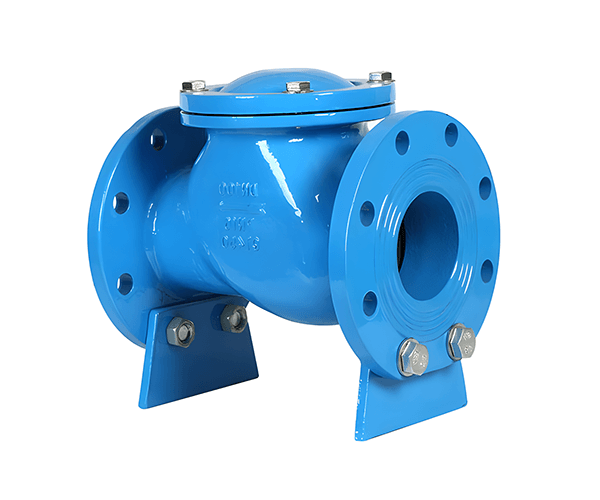

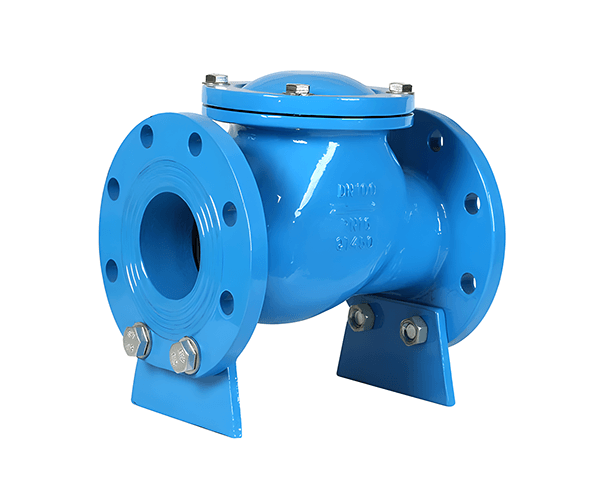

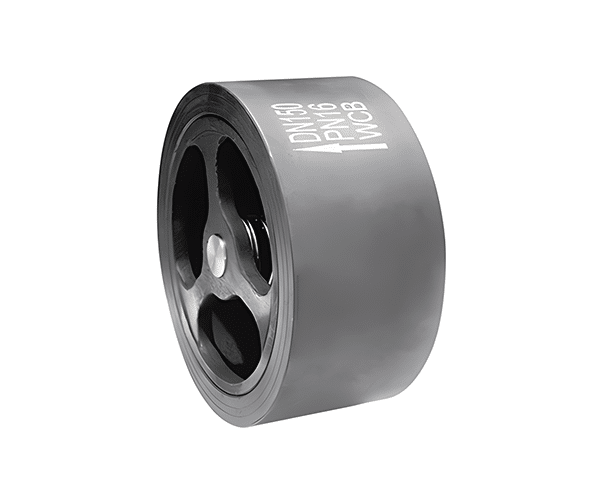

球型止回阀

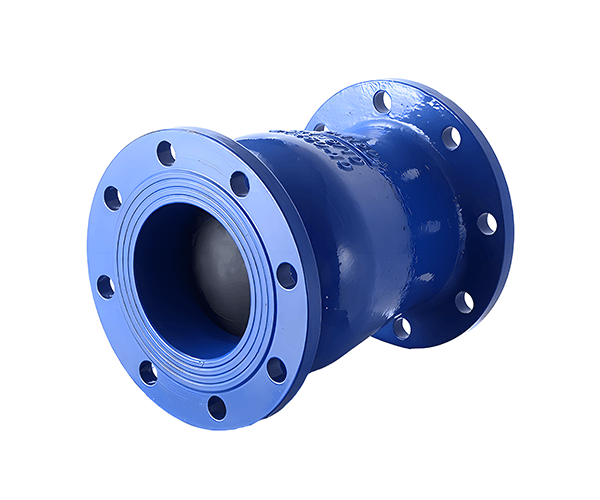

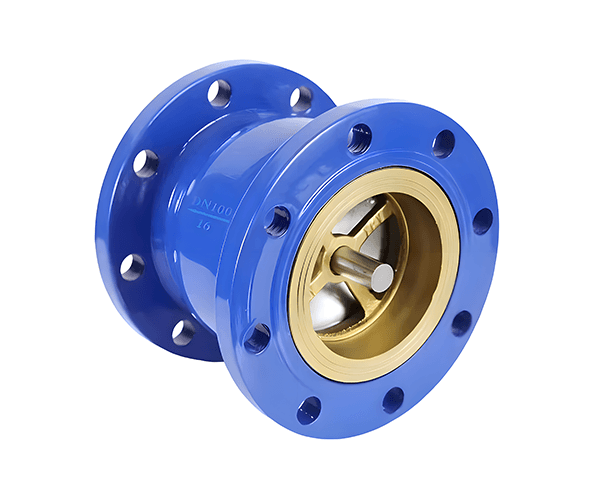

产品概述 | 球形止回阀是一款高效的单向阀,专为低压系统(≤PN16/Class 150)设计,用于防止水和含污泥介质的逆流。其坚固的结构和特殊功能使其成为可靠性、耐用性和易于维护性至关重要的应用的理想选择。 该阀门采用橡胶涂层球体,即使在污水处理厂和工业泥浆系统等磨蚀性或含颗粒环境中也能确保紧密密封。法兰连接设计(符合 EN 1092-1 或 ASME B16.5 标准)易于安装并集成到现有管道中,从而减少停机时间和人工成本。 该阀门专为低压供水系统设计,广泛应用于市政供水管网、雨水排放和消防系统。它能够处理污泥和泥浆介质(固体含量高达 30%),因此也适用于采矿、造纸厂和化学加工厂等工业应用。 |

工作原理 | 该阀门通过流体驱动执行机构进行操作: 1.正向流动:流体压力将橡胶涂层球体向上推,使流体顺畅流动,压降最小。 2.逆向流动预防:当流体停止或反向流动时,重力和背压迫使球体紧贴阀体,立即形成密封。 3.自清洁设计:球体在运行过程中的运动可清除密封表面的碎屑,非常适合污泥或含颗粒的介质。 |

主要特点 | 1.低压优化:额定压力为 PN10/PN16(EN 1092-1)或 Class 150(ASME B16.5),非常适合供水和污水处理系统。 2.橡胶涂层球阀:EPDM 或 NBR 涂层确保在磨蚀性/污泥环境中实现紧密密封和耐腐蚀。 符合 WRAS/ACS 饮用水安全标准。 3.法兰连接:EN 1092-1(PN16)或 ASME B16.5(Class 150)法兰,预钻孔,方便管道集成。 4.抗杂物:宽体设计可防止高固体含量介质(例如污水、工业泥浆)堵塞。 |

产品优势 | 低维护:无需润滑;可通过可拆卸法兰盖进行检查。 节能:低扬程损失(Kv 值 ≥ 0.8)可降低泵的能耗。 抗污泥能力:橡胶涂层可抵抗沙子、砂砾和纤维材料的磨损。 |

为什么选择我们 | 专为水/污泥量身定制:专业设计,避免脏污介质中常见故障。 快速交付:DN50-DN300 标准尺寸库存充足,7 天全球发货。 认证:ISO 9001 认证,符合相关法规要求。 节省成本:橡胶部件享有 5 年保修,降低生命周期成本。 |

总结

Product Parameters

| 公称通径 | DN50 to DN300 (2" to 12") |

| 公称压力 | PN10, PN16 (EN 1092-1) / Class 150 (ASME B16.5) |

| 适用温度 | -10°C to 80°C (EPDM) / -20°C to 60°C (NBR) |

| 阀体材料 | 球墨铸铁(EN-GJS-400-18),环氧涂层防腐 |

| 球体材料 | 不锈钢芯 + EPDM/NBR 橡胶涂层(符合 FDA/EC1935 标准) |

| 流动方向 | 水平或垂直(向上流动) |

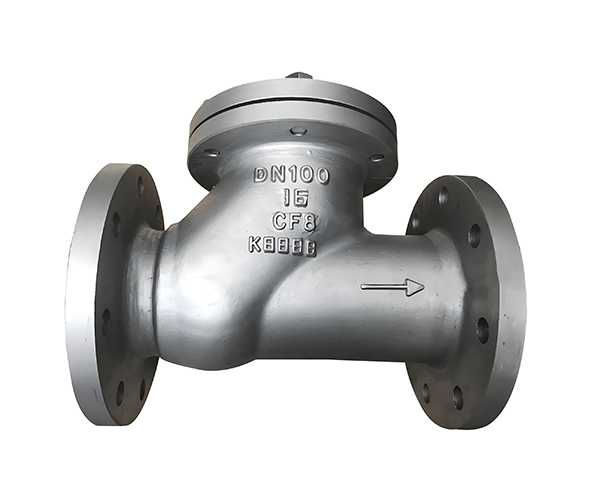

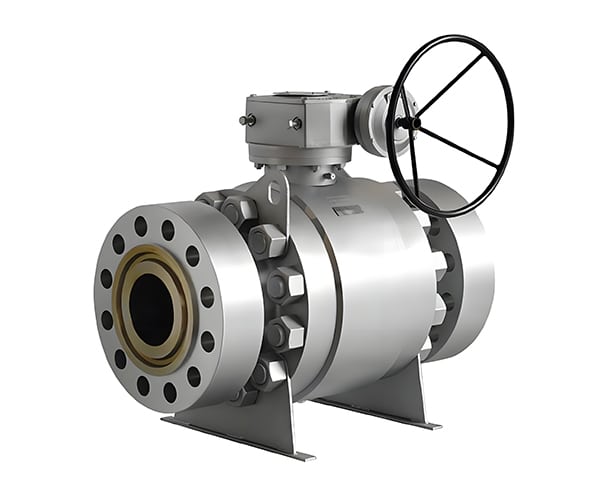

球型止回阀 相似产品

以下是类似产品。您可以搜索其他相关产品。